Founded In

Your Partner in Technological Excellence...

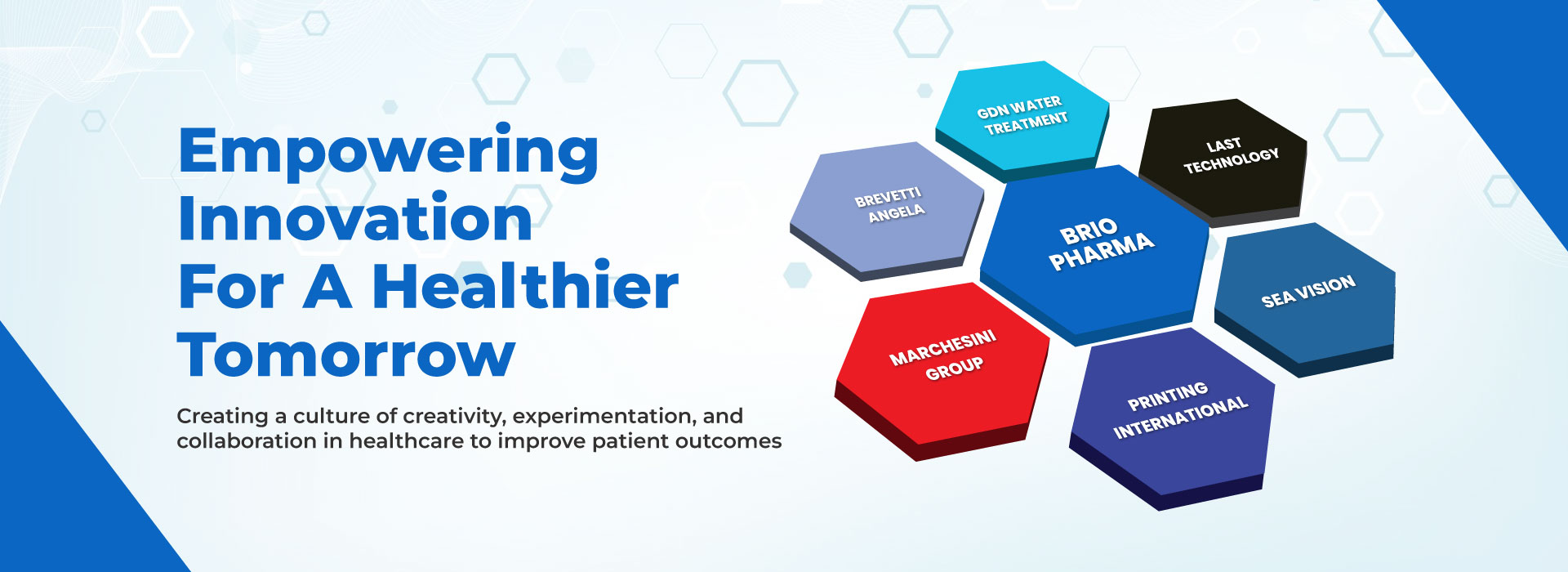

Brio Pharma Technologies was indeed formed in 2004 to provide technology solutions for the pharmaceutical industry’s complex processing and packaging needs. The company specializes in developing and manufacturing custom equipment and automation solutions for pharmaceutical manufacturing, with a unique edge, especially in the field of parenteral products such as injectables, vaccines, and biologics.

Deliver Best Packaging & Pharma Processing Solution

“Our principals are some of the industry leaders who are giving State-of-art machine.”

Marchesini Group

Marchesini excels in integrated packaging lines globally. Specializes in aseptic filling, inspection, serialization, and complete pharmaceutical packaging processes.

Brevetti Angela

Manufacturers of Blow Fill Seal machines for SVPs, LVPs, eye drops, WFI. Innovators in contamination-free liquid primary packaging designs.

Last Technology

LAST Technology, a 30-year leader in healthcare equipment, offers high-quality pharmaceutical washing, sterilization, and decontamination products for safe medicine production.

Sea Vision

Since 1995, SEA Vision offers advanced machine vision solutions for pharmaceuticals, ensuring total quality in products and packaging with proprietary algorithms.

Bormioli Pharma

Bormioli Pharma annually produces 7 Bn+ pharma packaging items, exporting to 100+ countries. A leading global glass bottle manufacturer.

Lameplast

Lameplast, an Italian leader in plastic packaging, specializes in pharmaceutical, medical, and cosmetic applications, emphasizing ophthalmic, vaccine, and inhalation solutions.

Printing International

Marchesini is one of the most renowned and reliable suppliers of fully integrated packaging lines in the world.

GDN Water Treatment

GDN, a 45-year-old firm, produces Water Treatment Plants for Pharma, including systems for Injectables, Purified Water, Steam Equipment, and Stainless Tanks using advanced technologies.

Accraply

Accraply, a Barry-Wehmiller subsidiary, is renowned globally for high-quality shrink sleeve label and tamper band application technology solutions.

Shubham Suresh Mishra

Mr. Shubham Mishra is the founder, main promoter, and Managing Director of the company, boasting a keen interest in technology and a proven track record as a serial entrepreneur. He specializes in introducing novel technologies and products with a focus on the pharmaceutical industry. His expertise extends to processing and packaging technology for injectables and solid dose forms, line engineering, assembly automation, New Drug Delivery Systems (NDDS), and medical devices.

With a wealth of experience exceeding 25 years, Mr. Mishra has successfully collaborated with leading organizations worldwide, making significant strides in their respective segments. His passion extends to clean and green energy, where he champions distributed power generation using Microturbines, Combined Cooling, Heating, and Power (CCHP), New and Renewable Energy (NRE), flare to power applications, and waste-to-energy solutions. In the highly competitive business landscape, he has consistently driven sustainability and growth.

of Experience

Projects Completed

Satisfied Clients

Why Us

Tailored Solutions for Critical Requirements in Pharma Industry

We provide customized solutions to meet the growing challenges of the pharmaceutical industry. Our decades of experience ensure optimal results.

Extensive Customer Database in India

Our vast and diverse customer database in India reflects our commitment to delivering value and building long-lasting partnerships.

Technically Qualified Team of Professionals

Our team of technically qualified professionals with expertise in the pharmaceutical industry stays up-to-date with the latest technologies.

Supply of High-End Machines with Innovative Technologies

We supply high-end machines with innovative technologies to improve production processes, and efficiency and reduce costs in the pharma industry.

News & Articles