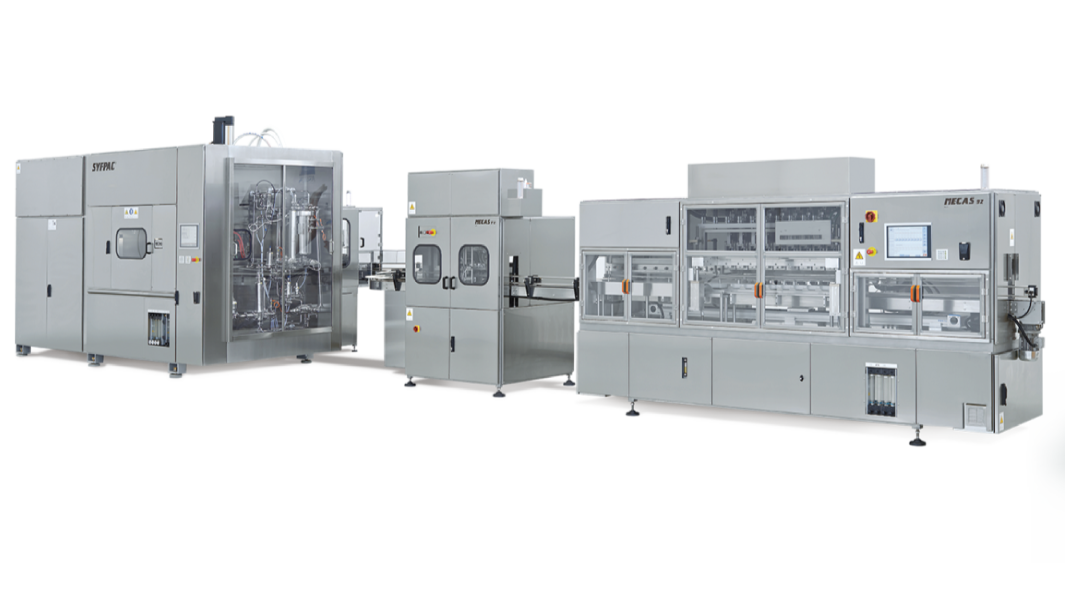

SYFPAC® LVP

LARGE VOLUME PARENTERALS

SYFPAC® LVP is engineered for the sterile primary packaging of Large Volume Parenterals, in plastic bottles that range from 50 ml to 1000 ml in volume and reach up to 2750 bottles per hour. It is apt for creating self-collapsing bottles similar to plastic bags and accommodating various formulations like for example IV solutions.

- Info

APPLICATIONS -

- IV Solutions

- Irrigation

- Disinfectants

- Veterinary vaccines

- Contact lenses liquid

- Eye wash

MAIN FEATURES -

- PRODUCTIVITY

SYFPAC® LVP machine can reach up to 2.750 bottles per hour and it can be provided with a full line for secondary capping along with MECAS machines. Suitable for mass production, the machine can work 24/7. - FLEXIBILITY

The moulds can work with either PP, LDPE or HDPE, with a simple change of recipe. This means that the bottles produced can be different in size and usability, even collapsible to the extent of imitating plastic bags. Inserts on the moulds can be quickly replaced for a swift format change. Custom made design allows production of containers from transparent to opaque, from very rigid to lightweight. - EURO CAPS

Wherever secondary capping is needed, SYFPAC® LVP machine can include a full line with MECAS cap assembling and cap sealing machines.

Euro caps or Inso caps are automatically placed on the bottles and sealed with injection moulding. ECO-HEAD DESIGN

Our patented Eco-head ® design allows a further cost reduction wherever

regulations do not require secondary capping and allow for a nipple-head bottle.

ADDITIONAL FEATURES:

- MASEP CUTTING UNIT: The optional MASEP unit can be incorporated for cutting, trimming, and separating into individual vials or smaller unit blocks.

- AUTOMATIC CIP&SIP: Cleaning In Place, Sterilization In Place, Drying and Integrity Tests are conducted automatically.

- INTUITIVE HMI: The machine HMI is crafted to be user-friendly and intuitive while adhering to the CFR 21 requirements for data integrity.

- PROGRESSIVE MAINTENANCE MONITORING: The machine autonomously tracks the required maintenance based on working hours and cycles, notifying the operator via the HMI.