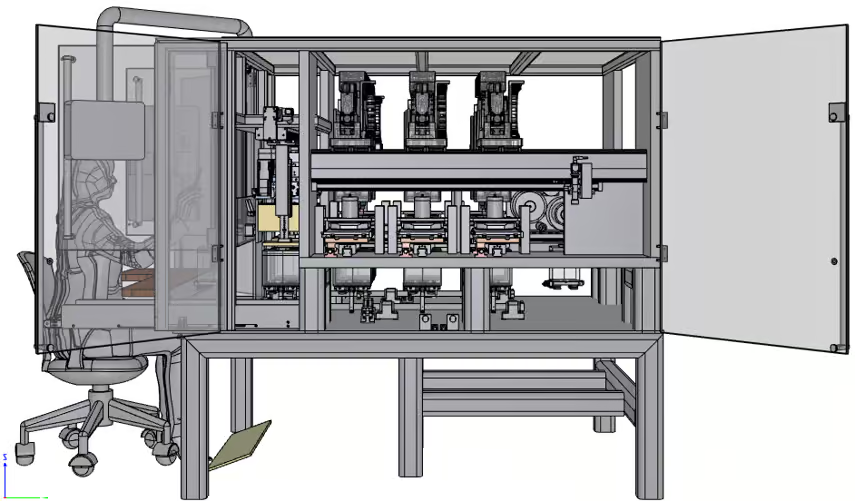

KRATOS

HIGH PRECISION / SHORT SET-UP TIME

The KRATOS represents a fully adaptable Next Generation pad printing machine suitable for diverse industries. Leveraging our patented technology, it attains top-notch print precision with minimal setup durations, facilitating swift transitions between images and products. A centralized recipe management system for the machine fleet ensures uniform and consistent printing across multiple units, irrespective of their physical placements. This guarantees consistent product quality regardless of the production location.

POSSIBLE PROCESS FEATURES –

Set up the ACR module automatically within seconds, ensuring the highest printing accuracy and enabling quick changeovers.

Camera inspection: print, assembly, orientation, tray full/empty

Camera inspection: print, assembly, orientation, tray full/empty.

Reporting: machine KPI, batch sampling.

Product handling : jig, vacuum

Pre-treatment: hot/cold air, plasma, flame, corona, UV, ionisation.

Automatic pad cleaning

Post-treatment: IR, NIR, hot air.

Assembly

Rejection: individual, batch, product samples.’

HMI remote position

Product transport: rotary table, LTS shuttle, linear shuttle, belt driven indexer.

MACHINE SETUP –

ROTA – The ROTA configuration is employed when the working stations are restricted, and there’s a need for optimal accessibility throughout the machine. By siting the working stations outside the product trajectory, each module becomes easily reachable by hand during production.

LINO – The LINO setup is implemented to maximize the number of working stations. Placed in a linear fashion, it enables the addition of features sequentially. This arrangement also ensures excellent accessibility from all sides.

RING – The RING setup is chosen when there are space constraints in the production area, and a compact machine design is essential. Placing all working stations inside the product trajectory saves space, though it may pose challenges in accessing specific parts during production.

GENERAL ADVANTAGES –

- Achieving the highest print precision

- Partnered with Siemens as an OEM

- Rapid changeover capabilities

- Compliance with cGMP and GAMP5 standards