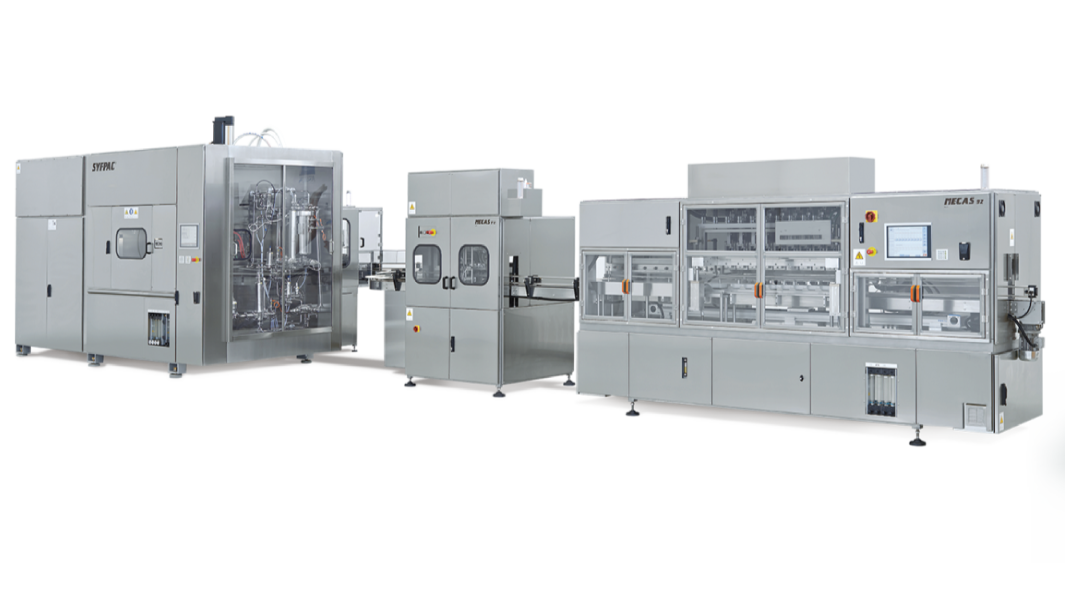

SYFPAC® LVP

LARGE VOLUME PARENTERALS

SYFPAC® LVP is engineered for the sterile primary packaging of Large Volume Parenterals, utilizing plastic bottles that range from 50 ml to 1000 ml in volume. It is apt for creating self-collapsing bottles and accommodating various formulations, with the capability to design up to 2500 ml for specialized applications.

- Info

- Technical Data

APPLICATIONS -

- Vaccines

- Ophthalmic solutions

- WFI (Water for Injection)

MAIN FEATURES -

- CAPACITY AND FORMS - SYFPAC® SVP: Adaptable volume range of 0.2 ml to 50 ml, modular molds with a maximum of 50 cavities for various shapes, inclusive of embossing/labeling. Capable of creating single and multi-dose formats such as 2 ml, 5 ml, 10 ml, and additional sizes using the identical mold.

CLEANING AREA: Minimized size reduces clean rooms to 36 sq m (Class C/D). An optional Ultraclean technology divides areas for saving space.

PRODUCTION SPEED - SYFPAC® SVP machine: Produces 16,000 units/hr (upgradeable to 25,000 uph), operates 24/7, durably constructed, and features intelligent maintenance.

ENHANCED VERSATILITY: Compatible with PP, PE, or HDPE for various formulations, ensuring durability during final sterilization and prolonging product shelf-life. Containers range from rigid to lightweight and transparent to opaque. Accurate parison thickness control diminishes plastic usage by up to 30%, enhancing vial squeezability and functionality.

SOLUTION CHARACTERISTICS - SYFPAC® SVP: Fills solutions ranging from 4°C to 30°C, making it suitable for heat-sensitive items like vaccines. It manages high-viscosity solutions, reduces foaming, and supports suspensions with recirculation systems.

ADDITIONAL FEATURES:

MASEP CUTTING UNIT: The optional MASEP unit can be incorporated for cutting, trimming, and separating into individual vials or smaller unit blocks.

INERT GAS INSERTION: The option to add Nitrogen or another inert gas atmosphere inside the vial is available.

GRADE A ZONE: The filling area is fitted with Hepa filters to minimize airborne particles and includes a port for particle monitoring.

INTUITIVE HMI: The machine HMI is crafted to be user-friendly and intuitive while adhering to the CFR 21 requirements for data integrity.

CAPACITIES AND PRODUCTION: Various volumes can be manufactured in the same machine. For instance, 0.2 ml to 10 ml with the peak output ranging from 17,000 to 15,000 units per hour.

AUTOMATED CIP & SIP: Cleaning In Place, Sterilization In Place, Drying, and Integrity Tests are conducted automatically.

PROGRESSIVE MAINTENANCE MONITORING: The machine autonomously tracks the required maintenance based on working hours and cycles, notifying the operator via the HMI.

Model | Container format | Number of cavities | Theoretical hourly output |

LVP 14 | 50ml / 100 ml ( ecohead ) | 14 | 3750 / 3700 |

LVP 10 | 100ml / 500 ml | 10 | 2520 / 2500 |

LVP 8 | 100ml / 500ml / 1000ml | 8 | 2015 / 2000 / 1690 |

LVP 7 | 100ml / 500ml / 1000ml | 7 | 1760 / 1750 / 1440 |

LVP 6 | 100ml / 500ml / 1000ml | 6 | 1510 / 1500 / 1270 |

LVP 5 | 100ml / 500ml / 1000ml | 5 | 1 260 / 1250 / 1060 |

LVP4 | 1000ml / 2 000ml | 4 | 845 / 740 |