- Info

- Technical Data

Applications:

- Utilization of Euro Caps

- Implementation of Inso Cap

- Absence of a secondary cap

Main Features:

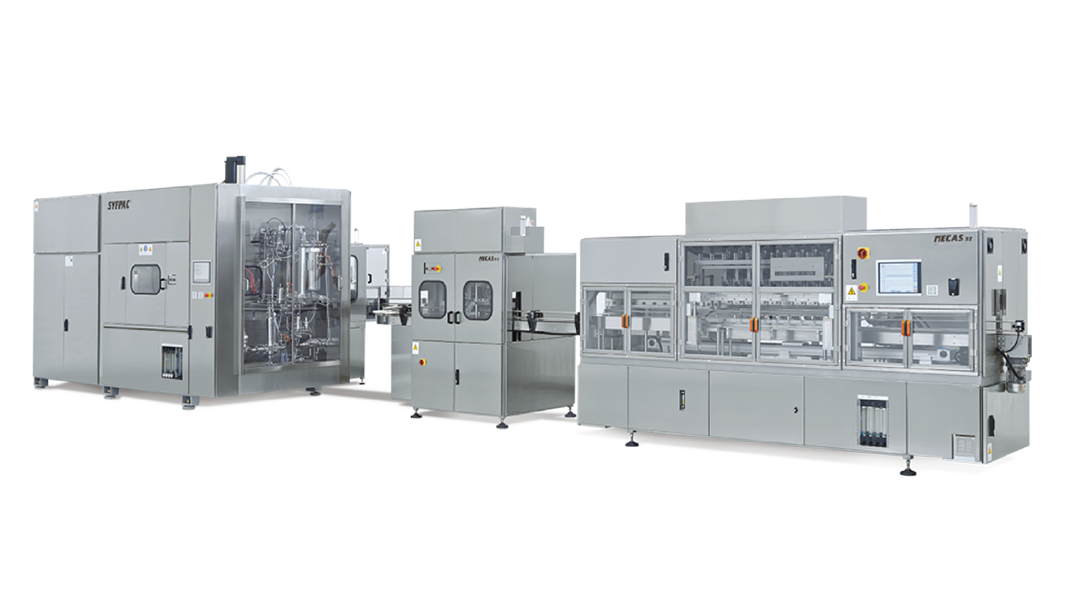

- Features: The system incorporates two units within the LVP line. Initially, the MECAS T2 station assembles plastic caps onto sealed bottles and introduces a water drop for injection between the cap and container head, ensuring effective sterilization. Subsequently, the bottles are directed to MECAS 9Z, where hermetic cap sealing is performed through injection molding, utilizing individual hot-runner units for meticulous control.

- Production Space: The T2 unit occupies a space of 3.8x3.4x2.7 meters, while the 9Z unit requires 5.4x3.4x2.7 meters. A comprehensive LVP line can commence from a total length of 11 meters, subject to layout.

- Production Rate: Mirroring the SYFPAC® LVP machine's production capacity, the MECAS system can cap and seal bottles at a rate of 2500 bottles per hour.

- High Adaptability: The MECAS system can assemble various Euro-cap types, accommodating prevalent market products: one or two-tab caps, insocaps with aluminum foil, 2-port caps for IV solutions, and twist-off caps. Both PP and PE caps are compatible, with a standard diameter of 31 cm. Custom solutions for caps of alternative designs or sizes are available upon request.

- Sealing Characteristics: The bottle cap is sealed with a plastic ring through injection molding, ensuring a flawless seal and visible sealing indication. This impeccable seal avoids leaks between the cap and bottle collar, guaranteeing no liquid spillage from any bottle section.

Additional Features:

- MECAS T2: MECAS T2, positioned as the initial station post the LVP machine, is tasked with cap assembly onto the sealed bottles.

- MECAS 9Z: MECAS 9Z, the subsequent station in the sequence, affixes the cap to the bottle using a plastic ring, with the injection molding of the ring ensuring a leak-proof seal.

- Euro Cap: While containers produced by BFS machines are hermetically sealed and sterile, certain regions necessitate additional closures for simplified dispensing, with Euro Cap being a prevalent choice.

- Alternative Cap Types: Beyond Euro caps, a diverse array of additional closures is accessible, necessitating a judicious selection based on cost and functionality.

- Cap Orientation: The system can also facilitate cap orientation prior to placement, ensuring the spike never penetrates the bottle head's parting line upon insertion.

- Automated System: The fully automatic system is equipped with a comprehensive SCADA system and features a 14-inch display, offering a user-friendly interface to monitor crucial data such as productivity, various settings, and alarms.

- Remote Assistance: The machine is capable of remote assistance, enabling technicians to connect remotely as needed, assisting in swift problem troubleshooting.

Model | Container Format | Number of Cavities | Theoretical hourly output |

MECAS T2 MECAS 9Z | 100ml - 2000ml | 2 CAP ASSEMBLY STATIONS 9 CAP SEALING ZONES | 2520 |

Information Brochure

Receive the machine brochure in pdf format, directly in your e-mail inbox.